Minimize setup, cleaning, and changeover time with AI-driven sequencing.

Respect real-world constraints like shifts, maintenance, and available resources.

Change constraints or tasks and recalculate schedules instantly.

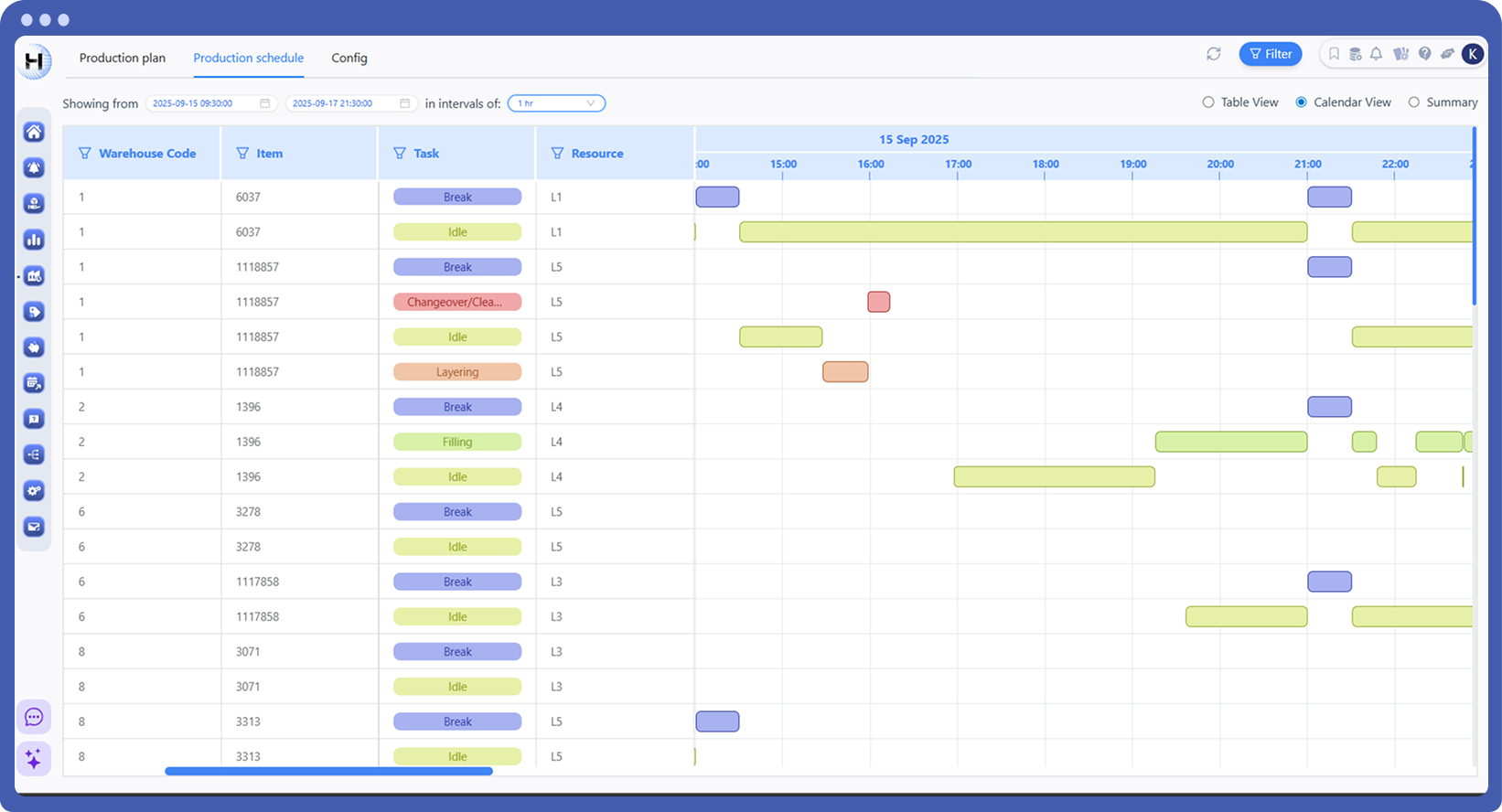

See all jobs, dependencies, and priorities in one calendar view.

Compare alternative sequences and pick the plan with best throughput.

Stay in sync as demand or capacity change — schedules adjust automatically.

Frequently asked questions

-

How does detailed production scheduling help manufacturers manage day-to-day operations efficiently?

Detailed production scheduling takes your master production plan and turns it into a precise, hour-by-hour execution roadmap.

It answers critical questions like:

Which machine will run which batch?

Which operator or workstation will handle each job?

When exactly will each order start and finish?

Unlike high-level planning, detailed scheduling focuses on real-time shop-floor realities machine availability, shift timings, setup durations, and urgent order priorities.

When done right, it keeps your production lines synchronized, avoids idle time, and ensures every order moves through the system smoothly bridging the gap between strategy and execution. -

How are AI and Machine Learning enhancing detailed production scheduling?

AI doesn’t replace your production scheduler it amplifies decision-making by turning complex factory data into actionable insights.

Here’s how AI and ML help in real-world scheduling:

Automating rule setup: Translating business rules and capacity limits into optimization parameters.

Predicting downtime: Forecasting machine failures or maintenance needs using historical data.

Spotting inefficiencies: Identifying hidden delays, over-allocations, or suboptimal sequencing.

Still, the core of production scheduling relies on Finite Capacity Scheduling (FCS) and Mixed-Integer Programming (MIP) mathematical engines that ensure every constraint is met.

Think of AI as your co-planner: it predicts and advises, while optimization models execute and balance the schedule." -

What real-world constraints should planners consider when creating a detailed production schedule?

A detailed schedule is only as good as the constraints it respects. Every factory runs under limits time, labor, machines, and materials and ignoring any of them leads to chaos on the shop floor.

Key constraints include:

Machine availability & setup times: Minimizing changeovers and ensuring machines are ready when needed.

Labor & shifts: Matching the right skills to the right job within available working hours.

Material readiness: Aligning production starts with material arrivals to avoid stoppages.

Process dependencies: Sequencing steps logically for example, coating or packaging only after prior steps are done.

Order priorities: Managing urgent and high-value orders without delaying standard production.

Regulatory & quality checks: Factoring in inspection times and compliance requirements.

A robust finite capacity schedule brings all these elements together dynamically ensuring every plan is realistic, executable, and conflict-free. -

How does production scheduling software simplify detailed scheduling for planners?

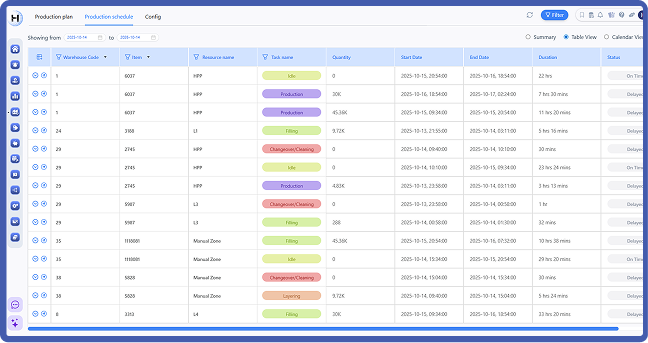

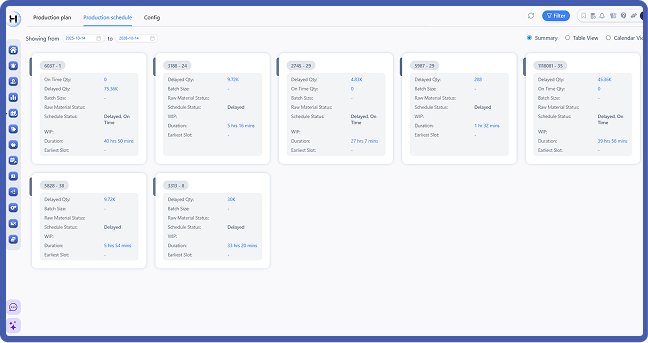

Modern production scheduling software transforms complex shop-floor decisions into a visual, automated process saving planners hours of manual rework.

It supports detailed scheduling by:

Balancing constraints automatically: Ensuring production fits within available machines, labor, and materials.

Scenario simulation: Allowing planners to test different plans and instantly see the impact.

Sequence optimization: Reducing changeovers and setup losses between batches.

Real-time adjustments: Dynamically reshuffling tasks when breakdowns or rush orders occur.

Instead of manually adjusting spreadsheets, the software recalculates the entire plan giving planners a real-time, data-driven control tower for factory operations. -

How does Horizon’s Detailed Production Scheduling module empower modern manufacturing teams?

Horizon’s Detailed Production Scheduling module is built for manufacturers who need speed, flexibility, and precision on the shop floor.

Here’s what makes it stand out:

Built-in Finite Capacity Scheduling (FCS): Plans that fully respect machine, labor, and material limits.

Custom constraint modeling: Capture your plant’s unique rulesfrom cleaning cycles to supplier delays.

Live schedule adjustments: Make quick edits and instantly rebalance the rest of the plan.

Integration with master planning: Connect long-term production goals with daily operational execution.

With Horizon, planners stay in full control while benefiting from AI-assisted automation, real-time insights, and end-to-end synchronization making production more predictable, efficient, and profitable.