Advanced inventory planning software

Improve your inventory planning process with automated stock policies, real-time alerts, and optimized replenishment proposals.

Inventory optimization

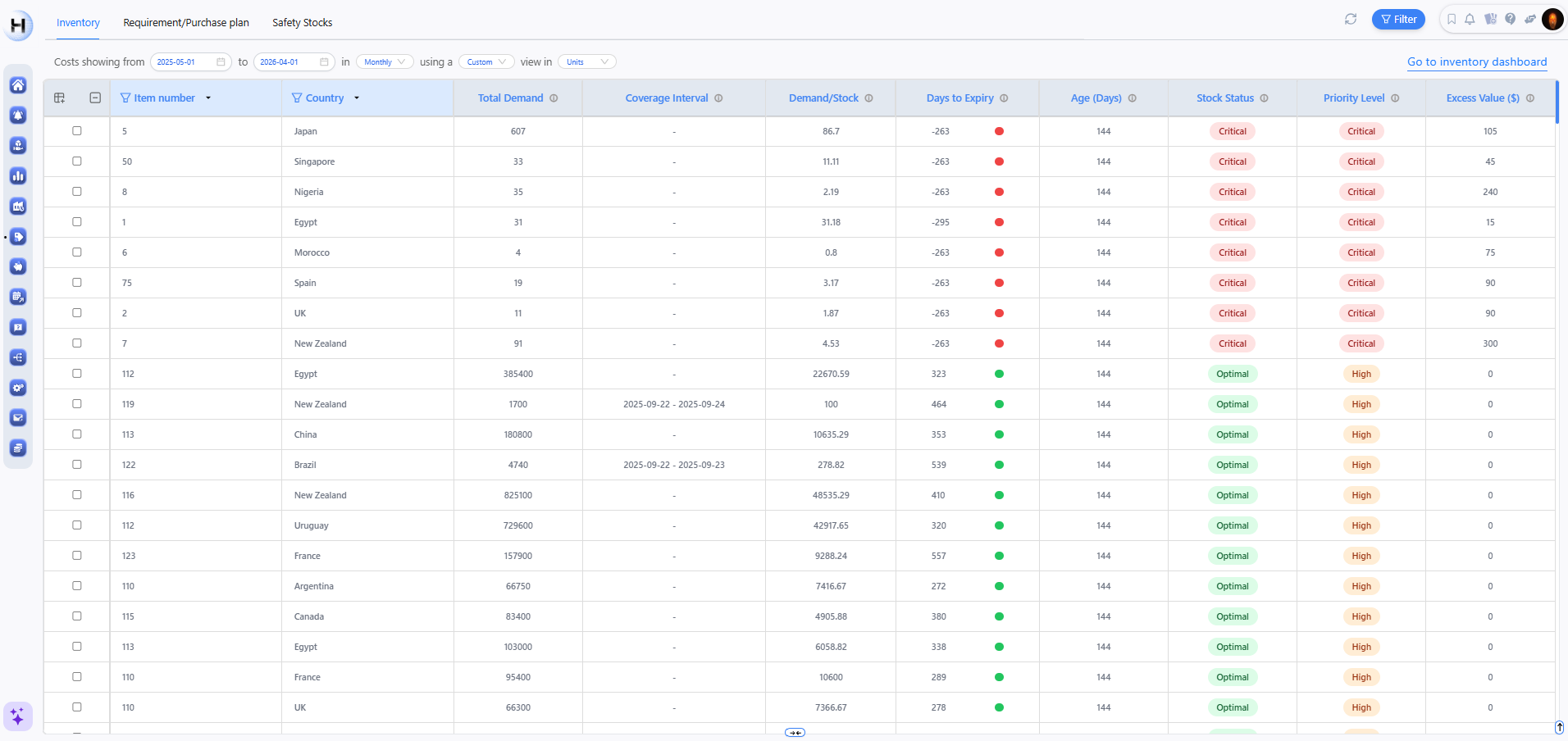

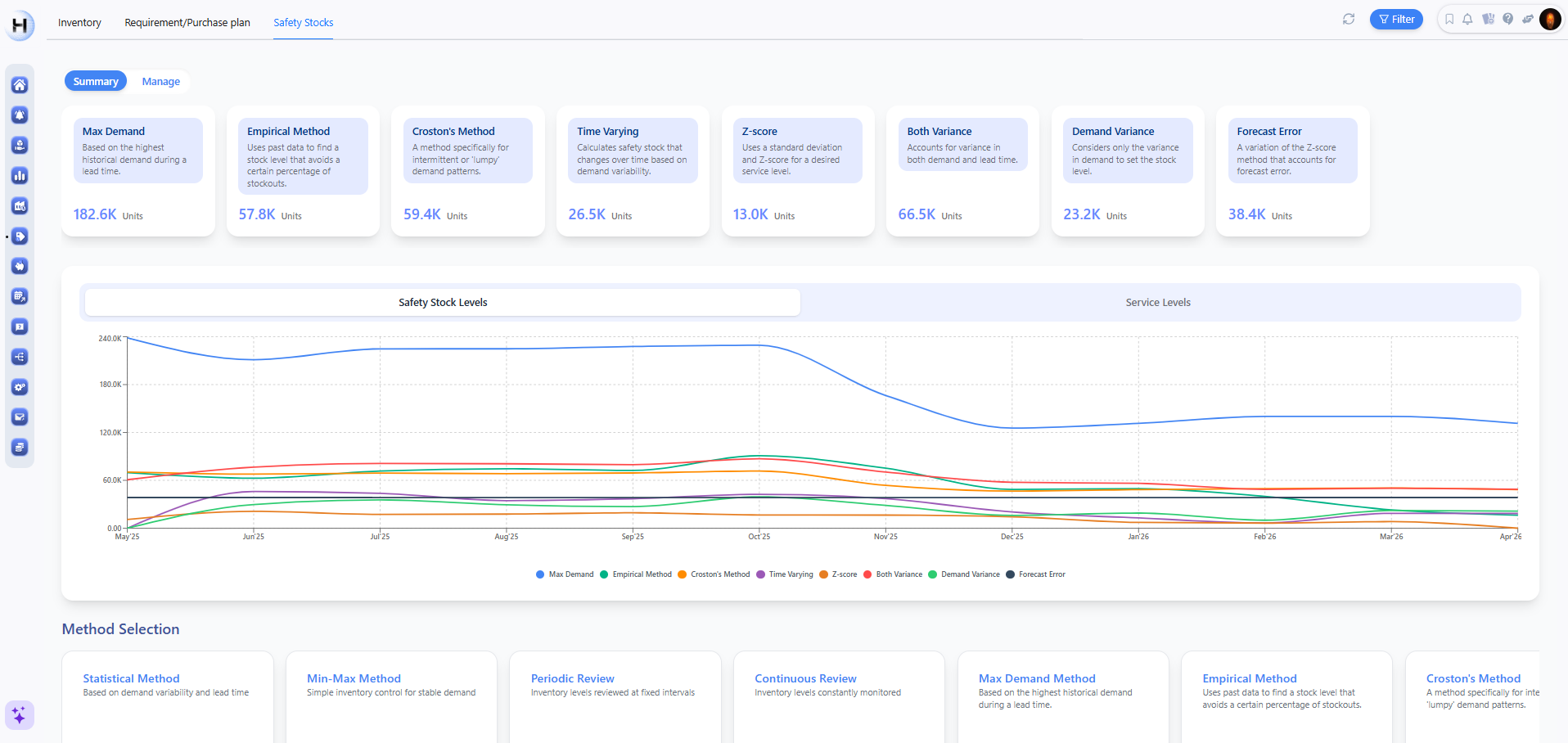

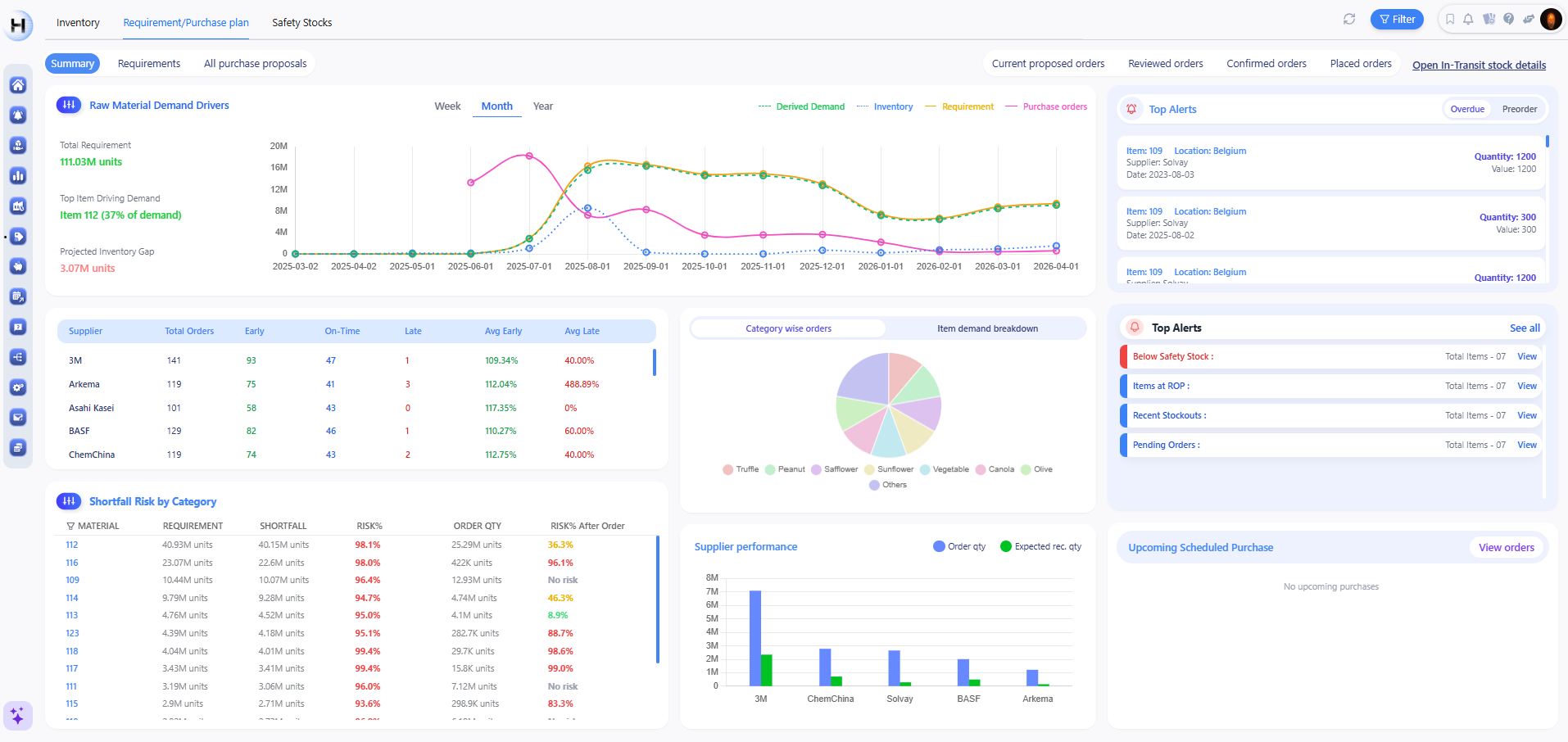

Horizon selects the best inventory policy per product and location, factoring in demand variability, lead times, and service levels. Multi-echelon optimization balances stock across the network.

Reduce excess inventory and prevent stockouts

Company benefits

Planner benefits

Purchase order and stock transfer proposals

Inventory optimization with Horizon

Optimal inventory policies

are determined for each product/location based on demand variability, lead times, and service levels

Fully customizable

Multi-echelon stock optimization

Rapid onboarding

Reorder and replenishment proposals

ERP integration

with SAP S/4HANA or as an SAP IBP add-on, Microsoft Dynamics 365, and Infor M3. Supports SFTP and APIs

Welcome to Dark World

FAQs

-

What is inventory optimization?

Inventory optimization ensures that the right inventory is available at the right location and time while minimizing excess stock, stockouts, and unnecessary holding costs. It balances demand variability, working capital, and constraints such as shelf life and lead times.

It is a crucial part of supply planning, ensuring that production and procurement decisions align with actual needs. By optimizing inventory, companies can reduce waste, improve service levels, and free up capital.

-

What are some inventory strategies?

There are different inventory strategies depending on business objectives. Some common approaches include:

- Basic strategies like setting a safety stock based on demand, reorder points, and min-max levels for replenishment.

- Optimization-driven strategies: setting service-level targets, working capital constraints, and balancing trade-offs between cost and availability.

- Multi-echelon inventory optimization (MEIO): optimizing stock across different locations in the supply chain to avoid inefficiencies in distribution and warehousing.

-

What is the role of machine learning/AI in inventory optimization?

AI (and mostly machine learning) plays a bigger role in demand forecasting, which directly feeds into inventory decisions, but inventory optimization itself typically relies on mathematical optimization techniques like linear programming or mixed-integer programming (MIP).

Where AI can add value in inventory optimization:

- Tracking demand shifts and recommending adjustments to safety stock.

- Detecting anomalies in stock levels and inventory movements.

- Translating business constraints into optimization-ready inputs, making the setup easier for planners.

-

How can software support in inventory optimization?

Inventory optimization software automates calculations and dynamically adjusts inventory recommendations based on demand changes. Key benefits include:

- Real-time inventory tracking and updates when new demand forecasts come in.

- Automated safety stock and replenishment calculations.

- Optimization models that consider costs, lead times, and service levels.

- Scenario planning to simulate different stocking policies and see their impact.

By integrating with demand planning and the ERP system, inventory software ensures that planners always have the latest, optimized stock recommendations.

-

What does Horizon offer in inventory optimization and replenishment?

Horizon provides an advanced inventory optimization solution that helps businesses balance stock levels, reduce excess, and improve service levels. Key capabilities include:

- Optimized inventory recommendations: considers business-specific constraints such as service levels, cost objectives, and supply chain limitations.

- Dynamic replenishment planning: generates replenishment proposals based on optimized stock levels, ensuring raw materials and finished goods are ordered efficiently.

- Seamless integration with demand planning: automatically updates inventory models when demand forecasts change.

- Customizable optimization goals: allows businesses to prioritize cost reduction, service levels, or working capital based on their needs.

With Horizon, companies can maintain the right stock levels while reducing costs and improving supply chain efficiency.