Production planning software

Production and capacity optimization

Balance capacity and ensure timely material availability

Company benefits

Planner benefits

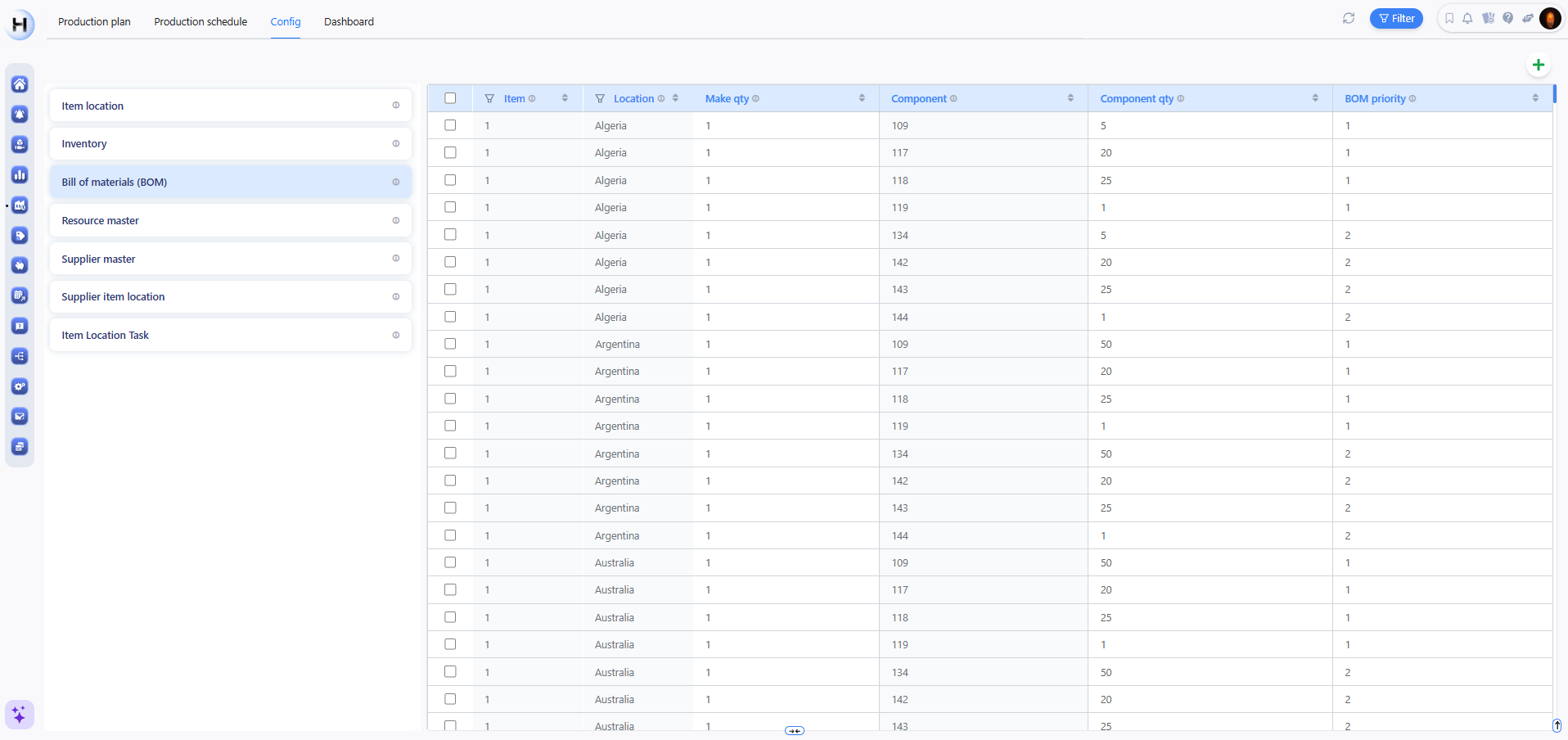

Purpose-built for your constraints

Every manufacturer operates under unique constraints like capacity limits and resource availability.

Horizon is flexible to incorporate your exact requirements.

Production planning with Horizon

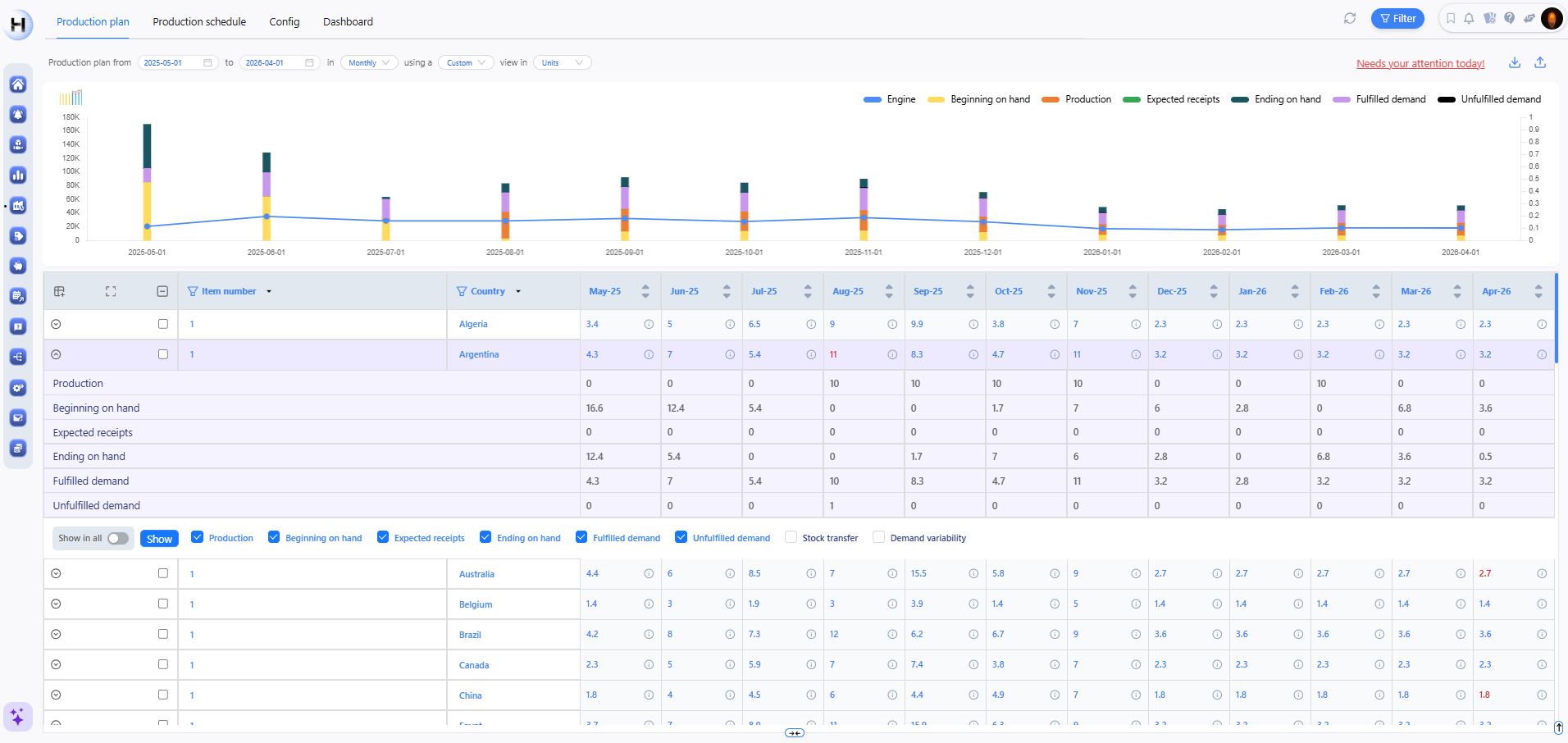

Dynamical MPS calculations

at monthly and weekly levels to account for demand plan changes and resource availability

Fully customizable

MRP runs

Rapid onboarding

Capacity balancing

ERP integration

with SAP S/4HANA or as an SAP IBP add-on, Microsoft Dynamics 365, and Infor M3. Supports SFTP and APIs

Welcome to Dark World

FAQs

-

What is production & capacity planning?

Production and capacity planning is about determining what to produce, when, and in what quantity, typically at a weekly or monthly level. It ensures that production schedules align with available capacity while balancing factors like workforce availability, energy costs, machine cleaning schedules, and holiday calendars.

Effective planning prevents bottlenecks and smoothens workload distribution across periods, avoiding extreme peaks and underutilization. It also considers whether to prepone production based on demand and inventory requirements, ensuring efficiency and cost control.

-

What should be included in a production schedule?

A well-structured production plan should include:

- Production quantities: how much of each product or category needs to be produced.

- Assignment to production lines/facilities: determining where each batch will be produced.

- Capacity utilization: ensuring production is balanced across periods to avoid overload or idle time.

- Buffer planning: reserving capacity for urgent or late orders if necessary.

- Workforce constraints: factoring in labor availability, shift patterns, and contract limitations.

By integrating these elements, production schedules help manufacturers optimize efficiency and meet demand while controlling operational costs.

-

What is the role of machine learning/AI in production planning?

Unlike demand forecasting, where machine learning plays a major role, production planning relies more on mathematical optimization techniques such as linear programming and mixed-integer programming (MIP). However, AI can assist by:

- Translating business constraints into model-ready formats to simplify setup for planners.

- Predicting process bottlenecks and recommending adjustments.

- Providing decision support by evaluating historical trends in machine utilization and workforce efficiency.

Despite these contributions, the actual scheduling and capacity balancing rely on optimization models rather than machine learning alone.

-

How can software support in production planning?

Production planning software automates complex calculations, ensuring constraints and priorities are optimally balanced. Key benefits include:

- Automated constraint-based scheduling: generating production plans that optimize for cost, efficiency, and service levels.

- Capacity balancing: ensuring workloads are distributed evenly over available production windows.

- Scenario planning: allowing planners to compare different scheduling approaches and understand trade-offs.

- Optimization vs. heuristics: unlike manual heuristics-based planning, which uses fixed rules, software can evaluate millions of possible schedules to find the best one for the business.

By leveraging optimization models, production planning software ensures decisions are data-driven, reducing inefficiencies and improving responsiveness.

-

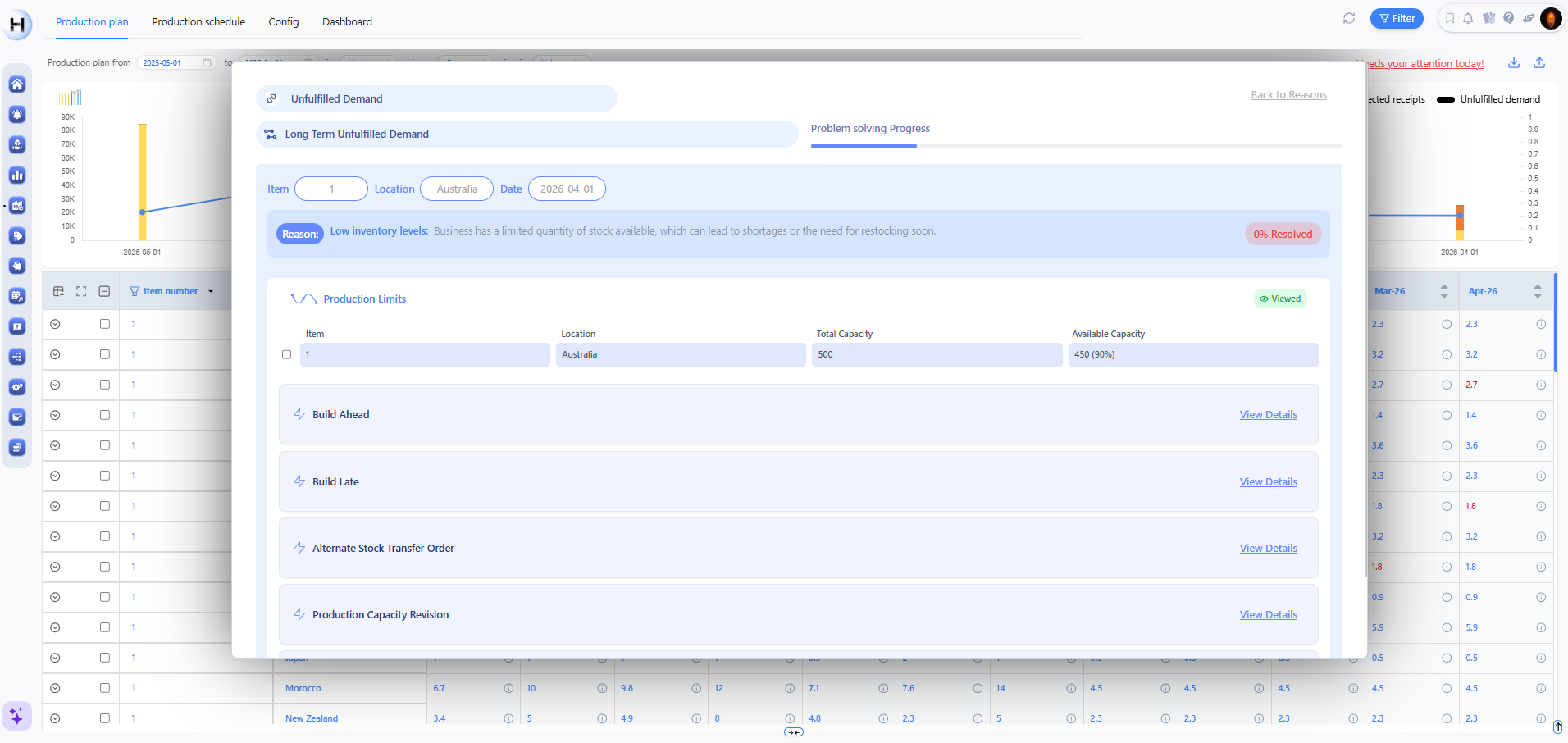

What does Horizon offer in production & capacity planning?

Horizon provides an advanced production planning solution designed to balance efficiency, flexibility, and business-specific constraints. Key features include:

- Built-in production scheduling models: preconfigured optimization techniques tailored to standard manufacturing objectives.

- Customizable constraints: easily include company-specific requirements such as labor rules, energy costs, and material availability.

- Priority-based scheduling: allowing planners to prioritize urgent orders, high-margin products, or other business goals.

- Material availability integration: ensuring that production schedules align with available raw materials, preventing shortages and delays.