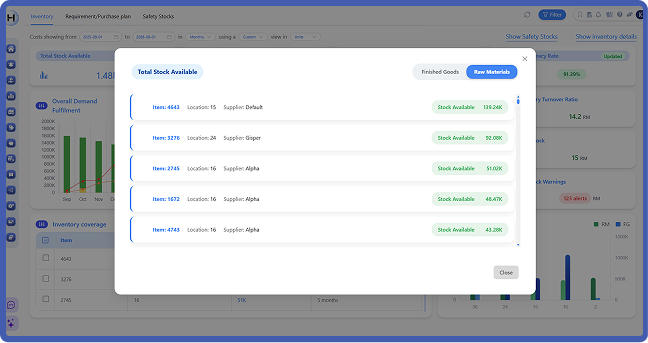

Plan inventory and replenishments across all sites simultaneously.

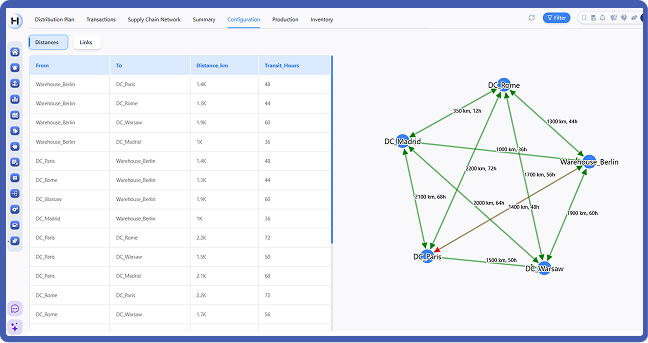

See flows, lead times, and stock levels across your entire network.

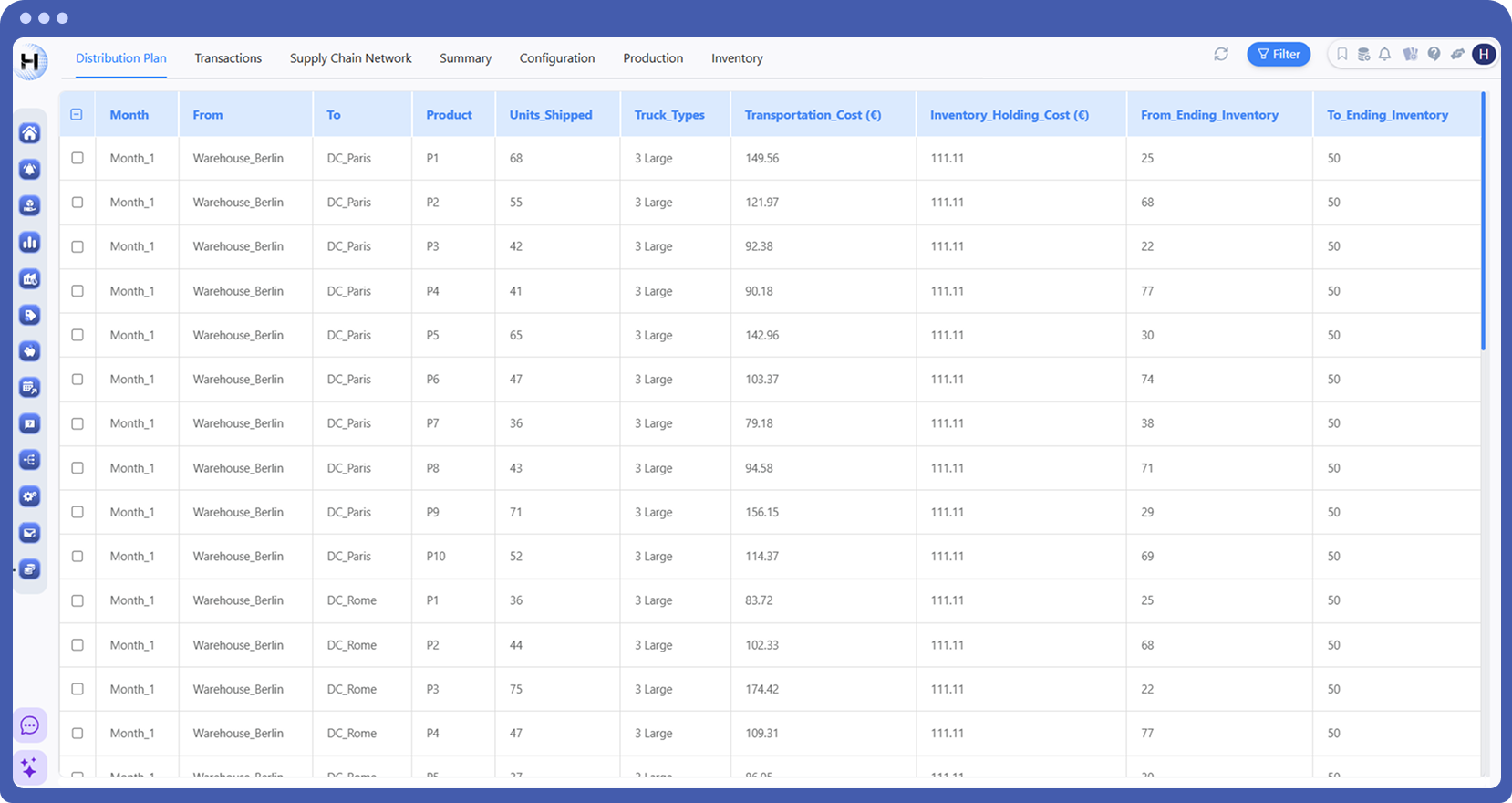

Optimize shipments by cost, lead time, or service level.

Define targets and constraints to guide replenishment and transfers.

Balance cost and service with MEIO logic for consistent availability.

Generate optimized transfer and replenishment plans automatically.

Frequently asked questions

-

What is distribution planning and why is it important?

Distribution planning determines how many units of each product should be delivered to each location or customer, based on demand, capacity, and cost. It ensures the right products reach the right place at the right time without overspending on transportation or holding unnecessary inventory. A strong distribution planning process improves service levels, lowers logistics costs, and keeps the entire supply chain synchronized.

-

How do companies decide how much inventory to ship to each location?

Most businesses use a combination of forecast data, safety stock requirements, transportation constraints, and service-level targets to determine optimal allocations. Modern distribution systems also run optimization models that consider costs, warehouse capacity, and customer priorities. The goal is simple: ensure every location has the right quantity not too much, not too little while minimizing logistics cost.

-

What role does optimization play in distribution planning?

Optimization models help planners decide the best way to distribute limited inventory across multiple locations. Using techniques like linear programming and mixed-integer optimization, the system evaluates thousands of possible allocation scenarios to minimize costs, avoid shortages, and respect constraints like truck capacity or warehouse limits. It replaces guesswork with data-driven decisions.

-

How does AI or machine learning improve distribution planning?

AI supports distribution planning by predicting demand shifts, spotting anomalies, recommending priority shipments, and identifying the most efficient distribution routes. It enhances planners’ decisions by analyzing historical patterns, customer behavior, and seasonality. While optimization decides what to ship where, AI helps predict why and when adjustments are needed.

-

How does Horizon support distribution planning and product allocation?

Horizon uses AI-supported optimization models to determine exactly how many units of each product should be delivered to each location or customer. It considers demand forecasts, transportation limits, warehouse capacity, and fulfillment priorities then generates the optimal allocation plan. With real-time updates, scenario modeling, and seamless ERP integration, Horizon ensures businesses always ship the right products to the right place at the lowest possible cost.